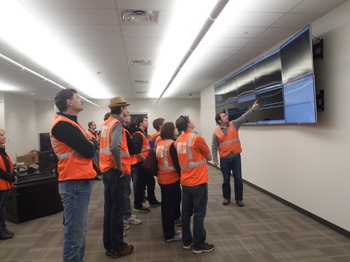

Hello Everyone! Lets take a moment to give a huge thanks to Fluor and the Denver Transportation Project (DTP) for letting us tour their CRMF (Commuter Rail Maintenance Facility). It was an amazing experience and we look forward to continuing our relations with Fluor. One of the Fluor employees, Randall, showed us the dispatch room for CRMF, which is the command and control center for the upcoming Commuter Rail line. Essentially, it is the brain of the system. Randall gave us a walkthrough of the control system, TMDS (Train Management & Dispatch System) and how they manage power usage. The CRMF facility, which is brand-new, was very well designed and quite impressive. Randall, as well as another Fluor employee Peter, gave us a description of the wide variety of careers and internships avaliable through DTP. Peter also mentioned that Fluor employs a large variety of different engineers.

every inch of the new trains. As someone who rides the light-rail every day, I am very excited to see the new improvements. The trains are powered by 25kV AC, and can go 80mph. One of the coolest (and greenest!) features are the regenerative breaks. These breaks feed power back to the system as the train slows down. Another green aspect of the CRMF is their work towards a LEED (Leadership in Energy and Environmental Design) certification by cleaning waste water, having power efficient lighting and radiant floor heating.

Team 4293 would like to thank Fluor and DTP for letting us experience this amazing facility! Thanks, Grayson

0 Comments

Leave a Reply. |

PhotosArchives

December 2016

AuthorGrayson Gerlich is a senior on the team and our webmaster. He also manages outreach content and team graphics. |

RSS Feed

RSS Feed